A gear is a device that transmits power by the engaging force of a tooth. It is a simple simple machine. Gears are a very basic but important element in mechanical element design. Let’s take a look at the concept of gear type, gear dimension, and strength.

There are various types of gears, which can be broadly classified into three types. The two axes of the gears can be divided according to whether they are parallel, intersecting, or staggered.

The types of parallel shaft gears include spur gears, rack and pinion gears, helical gears, and internal gears. A type of gear where two axes intersect each other is a barbell gear. There are hypoid gears, worm gears, and screw gears on the gears of the staggered shaft.

Gear Involute Curve

An involute curve is a straight line that is orthogonal to all tangents of an arbitrary curve. A characteristic of the involute curve is that the distance between the arc length on the original curve and the point on the involute cockline corresponding to the original curve is the same.

One curve has an infinite number of involute curves, but the distance between corresponding points on any two involute curves is always constant. The circle’s involute curve is applied to the cogwheel’s teeth and these gears are called involute gears. This gear is characterized by a constant pressure angle.

Gear dimensions

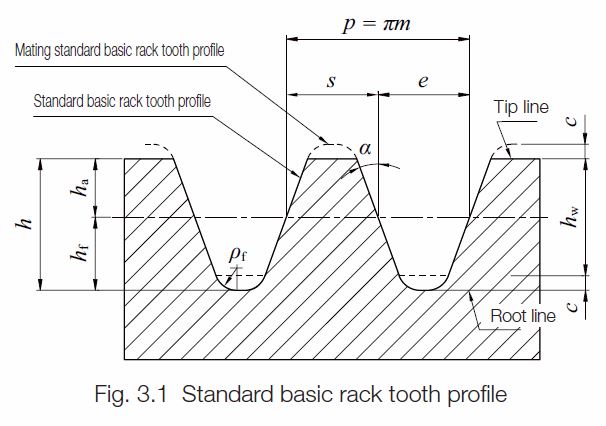

There are rack teeth that are the basis for involute gear teeth.

Like the teeth of this gear, teeth with a tooth height of 2.25 times the module are called standard teeth. This standard tooth type is the most common, but in some cases, a lower tooth type with a lower tooth height and a higher tooth type with a higher tooth height are also used. The pressure angle is generally 20 degrees, Special pressure angles such as 14.5 degrees and 17.5 degrees may be used

Gear strength

The criteria for calculating gear strength vary widely. However, the ISO standard (AGMA) is the most widely used, so let’s look at how to calculate the strength of AGMA.

1. Bending strength

In the evaluation of bending strength, the dangerous section is determined using H. Hofer’s 30 ° tangent method compared to AGMA using the inscribed parabolic method. The location of the worst-load action uses the highest point of this pair of gears as the worst-load action position.

The nominal stress is:

The bending stress is:

The allowable(permissible) bending stress is:

2. Surface pressure strength

Nominal contact stress is:

Pinion contact stress is:

Contact stress of gear is:

Allowable(Permissible) contact stress is:

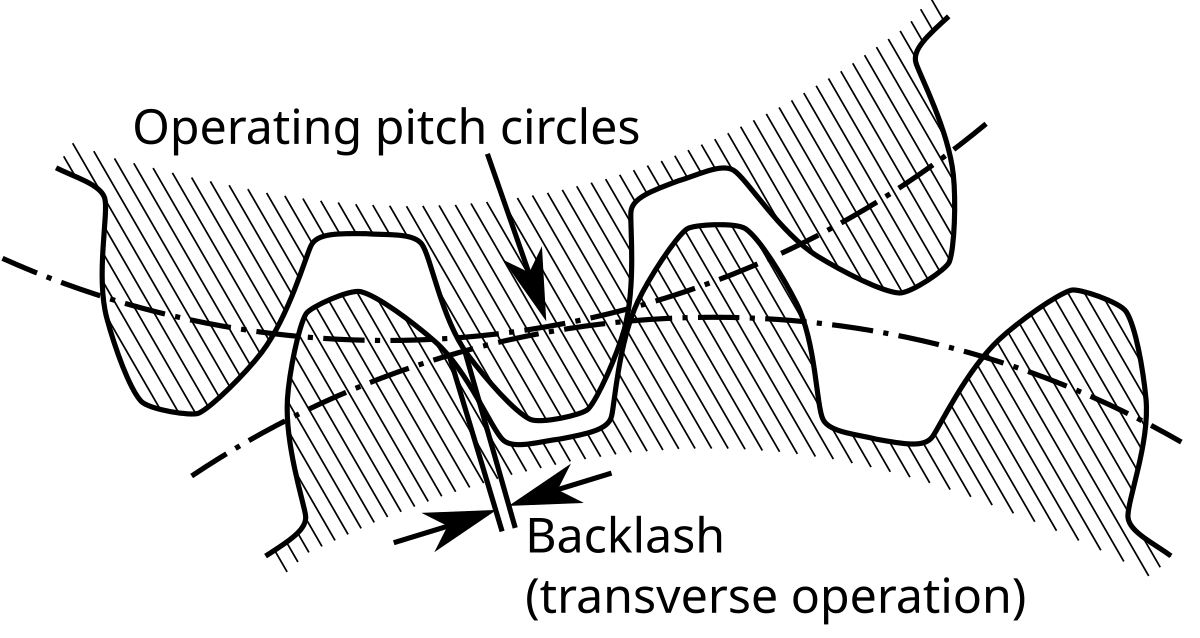

Backlash

Backlash is a gap created intentionally in the direction of movement in a mechanical device, such as a screw or cogwheel used in a machine, that moves in engagement with each other. The gap allows the screw and cogwheel to move freely.

However, when rotating in any direction, rotating in the opposite direction, displacement and impact may occur. When processing using a machine tool such as a milling machine, the dimensions must be adjusted in consideration of the backlash of the machine tool. In addition, because backlash increases due to wear, it causes vibration or noise and reduces the life of the machine.

Like!! Really appreciate you sharing this blog post.Really thank you! Keep writing.

I just want to say I am just very new to weblog and truly liked you’re page. Likely I’m likely to bookmark your blog post . You really have great article content. Bless you for sharing with us your blog.